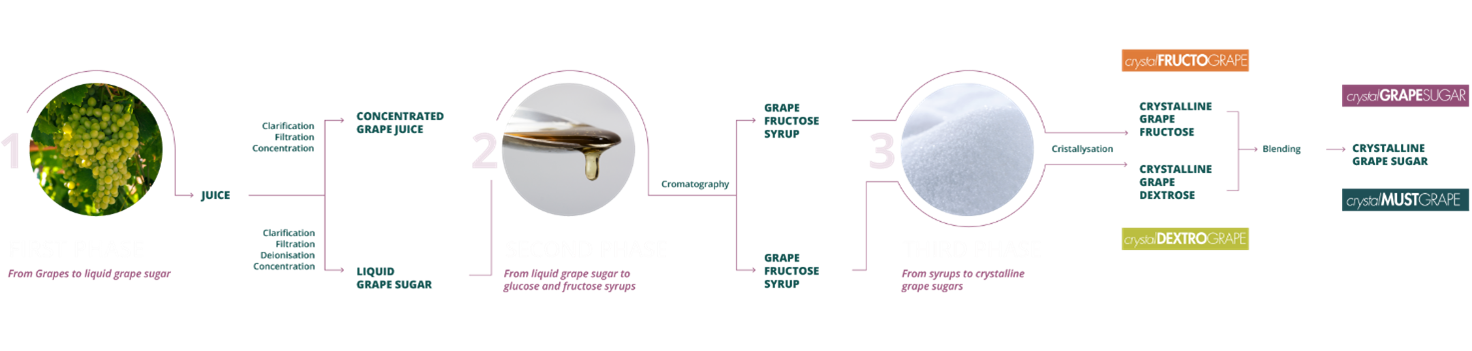

In the production process of solid rectified concentrated must (MCRS), the fructose and the glucose naturally present in the grape juice are extracted and crystallized without modifying their essential characteristics and therefore without altering their nature.

The technology involves a series of steps aimed at removing all the other components from the must to obtain a high purity glucose and fructose syrup (liquid MCR). This purification from “non-sugar” elements is based on a simple clarification process characteristic of wine production, using a natural clay called bentonite capable of favoring the precipitation of the protein fraction, which is then removed by filtration. A purification follows through the passage of the juice on ion exchange resins which retain impurities like organic acids and polyphenols, leaving the sugary components present in the treated product unaltered and thus making a pure solution of sugars.

Many years of research have indicated that the most useful way in the production of crystalline grape sugar starting from MCR is not its dehydration, but its separation into the individual constituents, glucose and fructose, each of which thus becomes crystallizable. Unlike the disaccharide sucrose, in fact, the two single monosaccharides do not crystallize easily when they are present in the same solution.

This possibility was offered by an innovative column chromatography technology containing an ion exchange resin which acts as a filter material for the components of the treated solution. The glucose and fructose of the MCR interact differently with the resin and are therefore characterized by a different retention time. Thus a different crossing speed and consequently the separation of the two sugars into two distinct solutions with a high level of purity is determined, then the two solutions are concentrated.

The subsequent crystallization phase is a continuous cold process, which involves the supersaturation of the sugars and the subsequent crystallization exclusively by cooling the solution in two separate crystallizers, with vertical development.

In this way, glucose and fructose are obtained in a crystalline and very pure state. The subsequent assembly of the two sugars by dry mixing in a ratio of approx. 1:1 therefore allows to reconstitute the glucidic principle of grapes in a solid state: to all effects, the crystalline grape sugar or MCRS.