INNOVATION

A responsible product,

innovative and good.

PATENTED TECHNOLOGY

NATURALITY

Fruit is a very important source of sugars (particularly glucose and fructose), but the pure products available on the market are not obtained from fruit.

Fructose in particular is known to all as “natural fruit sugar”, but not everyone knows that almost all commercial fructose does not originate from fruit: it is produced from starch or possibly sucrose, which originate from other vegetables (maize, rice, wheat, beet, etc.) that are not major sources of glucose or “free” fructose.

The various fruit products currently on the market are mainly found in syrup form (e.g. apple sugar, grape sugar) or in whole fruit form (e.g. coconut sugar, date sugar).

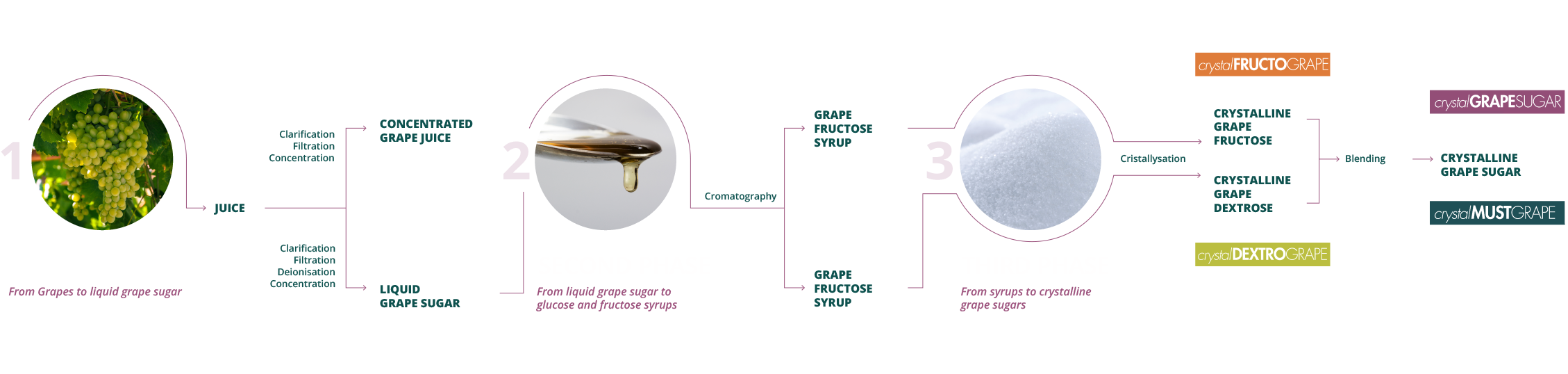

Thanks to technology developed by Naturalia, it is now possible to extract and crystallise the fructose and glucose naturally present in grape juice, without altering its essential characteristics. The sugars obtained from Naturalia therefore represent the authentic sugar component present in fresh grapes.

QUALITY AND PURITY

Crystalline grape sugars, glucose and fructose, have the same appearance as their traditional sugar counterparts derived from different raw materials. Their identity is however guaranteed and demonstrable through the analysis of isotope ratios and the assessment of the presence of traces of inositol, a characteristic marker of the grape.

In terms of quality and purity, crystalline grape sugars:

- derive from grapes of European origin;

- are pure products complying with the requirements of: Directive 2001/111/EC, Food Chemical Codex, Codex Alimentarius, EU Pharmacopoeia, US Pharmacopoeia. crystalMUSTGRAPE, produced from wine grapes and intended for the wine sector, also complies with Reg. (UE) No. 1308/2013;

- comply with EC Regulation no. 396/2005 on maximum residue levels of pesticides and also with EC Commission Regulation no. 1881/2006 setting maximum levels for contaminants in foodstuffs;

- do not contain allergens, nor is there any risk of cross-contamination (Reg. (EU) 1169/2011 and subsequent amendments);

- are obtained without the use of solvents other than water and are therefore free of residual solvents;

- do not contain any preservatives;

- are not and do not contain any “engineered nanomaterials”;

- do not contain, consist of or are not derived from GMOs as defined by EU regulation no. 1829/2003; no GMO ingredients are used in the production process of the product. Any risk of unintentional and accidental contamination is also excluded;

- the product and raw materials are not treated with ionising radiation (1999/2/EC, 1992/3/EC);

- are free of any animal substances and are not tested on animals. The production process does not use any ingredients of animal origin or come into contact with products of animal origin during storage and transport.

ADVANTAGES

Fruit sugars have special properties in addition to those of their constituent sugars.

From an organoleptic point of view, the synergy between fructose and glucose makes it possible to combine the immediate perception of sweetness typical of fructose, increasing its persistence thanks to the properties of glucose, but without masking the flavours of the matrices in which it is used, on the contrary, enhancing them.

Furthermore, compared to sucrose, invert sugars (dextrose and fructose) have different properties that play an important role in many food applications.

- They have a high affinity for water (particularly fructose) and are therefore used to retain moisture in products. This is important, for example, in bakery products where the inverted sugars help retain moisture and extend shelf life.

- They inhibit crystallisation and retain moisture, so are used in products such as icings, fillings and confectionery.

- They increase the dry matter content in their applications.

- They have a lower water activity than sucrose: this translates into a preservative effect, resulting in a longer shelf life.

- In bakery products, they enable both the Maillard reaction and the caramelisation process, producing a golden effect.

As far as nutritional aspects are concerned, sugars are characterised by a similar caloric value (4 kcal/g), but a different sweetening power, which allows them to be dosed differently to achieve the same sweetening result. Due to its high sweetening power (120% to 170 % compared to sucrose), fructose, in particular, can be used in lower concentrations, providing the final product with a reduced calorie intake.

Sugars differ in their impact on blood sugar. Glucose has a high glycaemic index (GI = 100), sucrose has a medium GI (approx. 70) and fructose a low GI (20-25). Fructose is therefore a sugar which, at correct intake levels, can be used by diabetics and is therefore suitable for use as a sweetener in products intended for this particular group of consumers.

A clinical trial commissioned from the University of Milan to determine the glycaemic index of grape sugars in comparison with “traditional” sugars confirmed low glycaemic index values for both crystalline grape fructose (IG=25) and grape sugar (IG=49).

The availability of fruit sugars in crystalline form, rather than in the traditional liquid forms (juices, syrups) has a number of advantages in terms of reduced environmental impact of logistics; increased opportunities and ease of use; simplicity of storage and stability.

In the wine industry, solid rectified concentrated must (to all intents and purposes a grape sugar of natural origin) is ideal for enrichment, sweetening and sparkling processes, as it combines the advantages of sucrose (pure and crystalline) with the origin of liquid rectified concentrated must, guaranteeing the integrity of the wine, chemical and microbiological purity, stability and ease of use