The practice of sweetening in oenology consists of adding sugar in various forms to the finished wine with the aim of increasing the residual sugar content. Appendix 10, part D of Annex I to Reg. (EU) 2019/934 establishes limits and conditions for the sweetening of wines, which can be done using grape must, concentrated grape must and rectified concentrated grape must, individually or combined. Sweetening with grape juice, partially fermented grape must or sucrose is generally prohibited for all types of wine.

The must and the concentrated must contain a significant quantity of primary and secondary metabolites of the grape, which, in the case of concentrated must, have undergone the same concentration as the sugars present in the must before concentration and, if not obtained from the same grapes used for winemaking, risk introducing typical notes of other varieties into the wine.

The rectified concentrated must, indicated by the acronym MCR, is instead purified of the phenolic, acid and mineral parts, remaining a natural hydrosugar mixture, and is therefore defined as “grape sugar”. However, the MCR does not yet represent an optimal solution from the point of view of purity, stability, logistical practicality and use.

As emerged from the “Wine4Wine” research project, managed by the Edmund Mach foundation, liquid MCR presents some varietal-type residual tracer compounds, typical of the original grapes, or process-type compounds produced following the heating of the must, which are also found in wines enriched with this sugar.

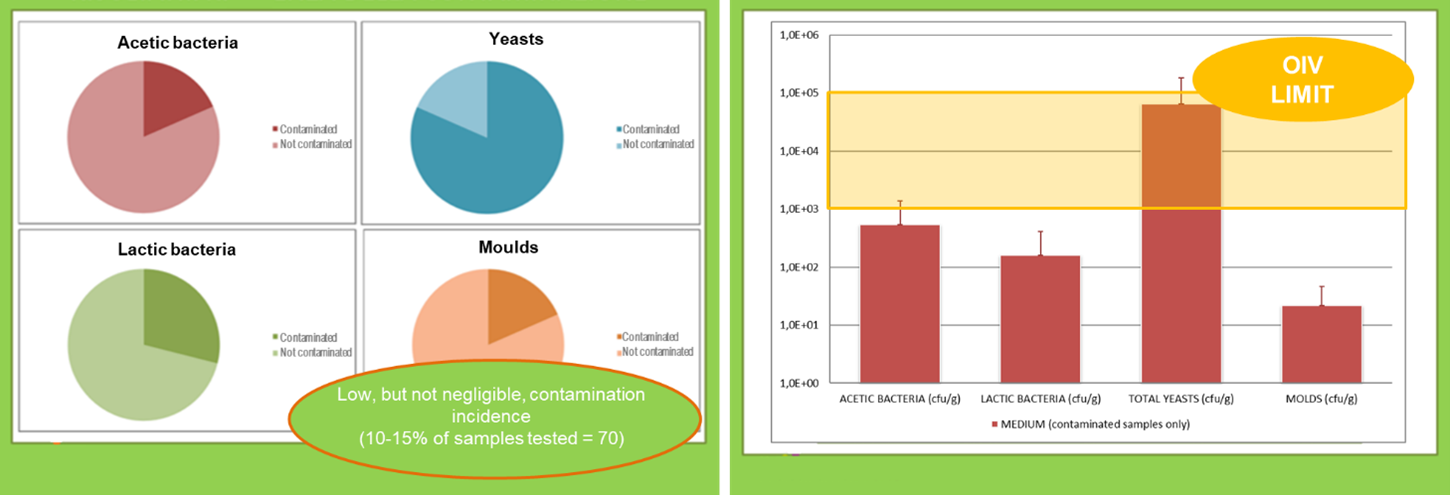

The presence of an abundant microbial population (yeasts, lactic and acetic bacteria, molds, Figure 1) was also observed in liquid MCR and during the sweetening phase the conveyance of this microflora risks interfering with the quality of the winemaking process.

The limits of musts, concentrated musts and rectified concentrated musts have been overcome with the introduction into the international market of MCR in crystallized form or Solid Rectified Concentrated Must (MCRS): an innovation 100% made in Italy and unique in the world, approved for all cellar practices (enrichment, sweetening, sparkling winemaking) from Regulation (EU) N.1308/2013.

As demonstrated by the Wine4Wine project, MCRS is characterized by absolute chemical and microbiological purity. From the point of view of the aromatic profile, MCRS appears much cleaner and free of volatile compounds compared to liquid MCR and is substantially free of microbial contamination potentially harmful to the quality of the musts and wines in which it is used.

The quality of the product, the simplicity of use and the absence of water also allow the sweetening dosage to be managed with extreme precision, guaranteeing maximum respect for the quality of the processed product.