The Wine4Wine project, conducted by the Edmund Mach Foundation, studied the effects of enrichment with Solid Rectified Concentrated Must (MCRS) compared to liquid MCR, through an experimental plan [1] which involved the analysis of the profile of volatile compounds in still wines added with the two forms of rectified concentrated must.

The methods of enrichment with MCRS are practically similar to those reported in the manuals involving the use of sucrose (which, however, as is known, is not permitted in Italy for this practice), since in both cases they are pure sugars in the solid state. Furthermore, the ICQRF in the annual harvest handbook specifies that the OIV resolution OENO 466-2012 is also applicable to calculate the increase in alcoholic strength using MCRS.

It can therefore be assumed that 1 kg of MCRS (which corresponds to a volume of 0.66 litres) develops 0.5943 (approximately 0.6) liters of alcohol and 1.68 kg of MCRS are used to increase 100 liters of wine by 1 degree of alcohol.

The enrichment tests were carried out using wines of the Müller Thurgau variety from 3 wineries (FEM, Vivallis and Mezzolombardo), for the Schiava variety the wines of 2 wineries (Mori Colli Zugna and Riva) while for Trebbiano Toscano and Sangiovese the wines of a cellar (Antinori and Frescobaldi respectively).

The wine samples obtained were analyzed in triplicate with the SPME technique in headspace and injected into a gas chromatograph. The analyzes focused on those wines that it was possible to maintain in a state of direct comparability, in separate tanks and in the same oenological conditions, until the moment of sampling. More than 1500 compounds were present in each chromatogram obtained.

The analysis of the principal components of the individual varieties highlights a separation between wines produced with liquid MCR (MCR) and solid MCR (MCRS), as in the case of Müller Thurgau (Figure 1).

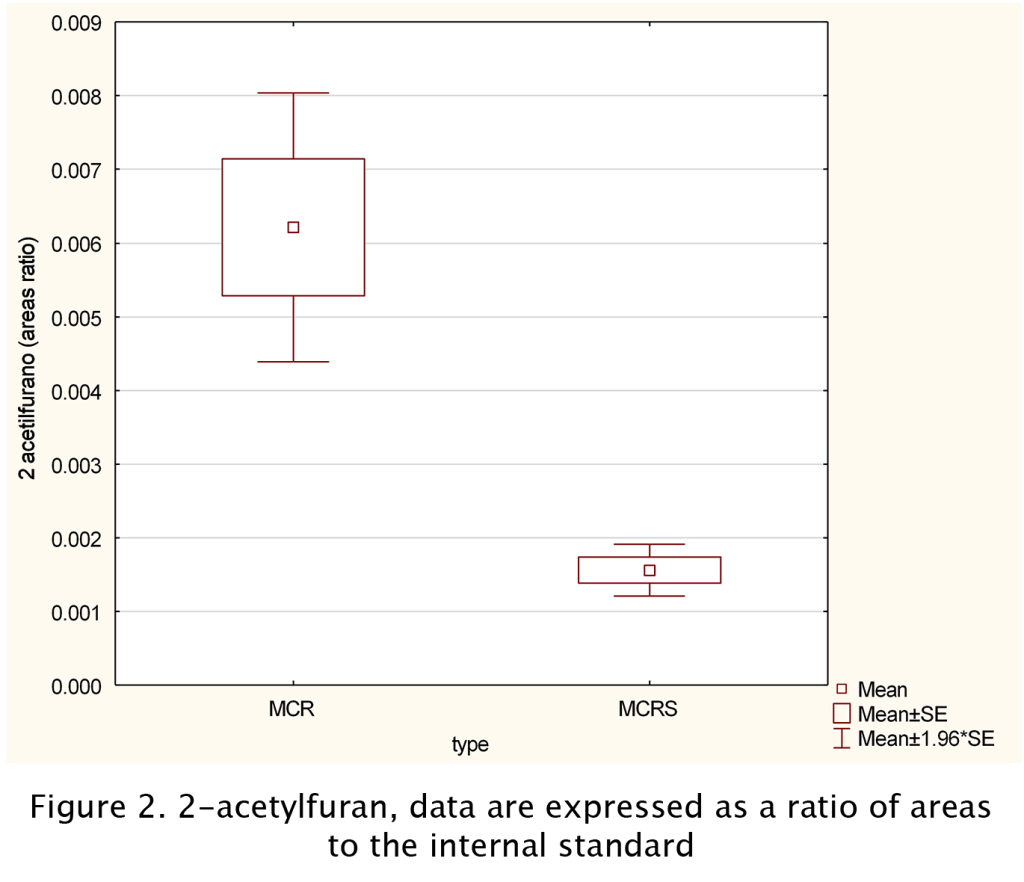

Among the compounds that most differentiate the two theories (MCR, MCRS), 2-acetylfuran stands out, a product formed from the Maillard reaction with heat, always present in greater quantities in wine produced with MCR (figure 2). This demonstrates that the MCR production process, operating at high temperatures, leads to the formation of some sugar degradation products.

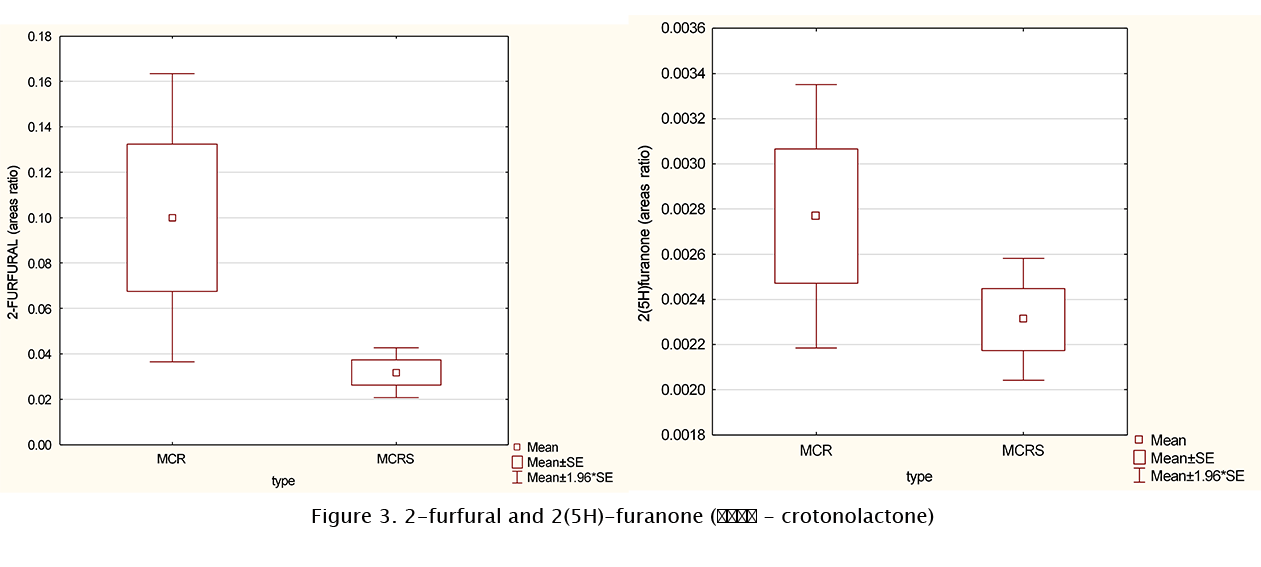

Other very different compounds in the two theses are: furfural (2-furancarboxaldehyde), 5-methyl furfural and 2(5H)-furanone, known as a, b – crotonolactone (figure 3), also attributable to the Maillard reaction and the caramelization process.

It has been highlighted that during the production process of sugar syrups, especially if the pH of the medium is acidic, there is a rather high formation of these compounds.

The formation of all these substances, together with dioxolanes, has also been described in fortified sweet wines during aging [2] [3].

Among the compounds present in greater quantities in products vinified with MCRS, beta-damascenone was observed (figure 4: cis and trans isomers), a compound which always provides highly appreciated fruity/floral notes and with extremely low olfactory thresholds.

In various studies [4] [5], it has been highlighted that the importance of this compound is not only due to its olfactory notes, which are much sought after, but to the fact that it manages to enhance some positive fruity notes and mask others that are too herbaceous and which would therefore have a particular importance especially in red wines.

Two compounds attributable to the chemical class of phenols were then observed which are greater in wines produced with liquid MCR: guaiacol and eugenol, the origin of which remains doubtful (according to the literature they may be of bacterial origin) [6].

As regards the content of terpenes, no significant differences are found although for some compounds such as rose oxide and the furan oxides of linalool there appears to be a greater quantity in wines produced with liquid MCR, as well as for some C13-norisoprenoid compounds, such as vitispirans and TDN.

Even in the case of Schiava, the principal component analysis can distinguish the samples produced with liquid and solid MCR. The compounds that most differentiate the two groups (as has already been seen for Müller Thurgau and as for Trebbiano Toscano) are those of the Maillard reaction favored by heat such as acetylfuran, 2-furfural and 5-methylfurfural.

Beta-damascenone is also higher in wines produced with MCRS and this could bring positive notes to the wines and also contribute to the exaltation of fruity notes.

Sangiovese is distinguished from other (white) wines by the presence of allyl isocyanate.

An observation that is not immediately interpretable is that in all varieties the presence in greater quantities of some undesirable hydrocarbons such as dodecane, tridecane, tetradecane and heptadecane was also observed in association with the test with liquid MCR.

It can therefore be concluded that the use of liquid MCR can bring foreign substances to the wine both originating from the heating of the must during the production process and deriving from the original grapes. These volatile substances “alter” the profile of the finished wine, and in some cases the differences can lead to olfactory sensations of sensorial relevance.

[1] Naturalia Ingredients: per vinificare 100% da uva. L’Enologo n.11 – Novembre 2020.

[2] Ghaderi, Faranak et al. Effect of pH and Storage Temperature on 5-(Hydroxymethyl) Furfural (5HMF) Formation in USP Syrup Preparation. Pharmaceutical Sciences 21 (2015): 1-5.

[3] Cutzach I, Chatonnet P, Dubourdieu D. Influence of storage conditions on the formation of some volatile compounds in white fortified wines (Vins doux naturels) during the aging process. J Agric Food Chem. 2000 Jun;48(6):2340-5.

[4] Pineau, B.; Barbe, J.-C.; Van Leeuwen, C.; Dubourdieu, D. Which Impact for β- Damascenone on Red Wines Aroma? J. Agric. Food Chem. 2007, 55 (10), 4103–4108.

[5] Mendes-Pinto, M. M. Carotenoid breakdown products the—norisoprenoids—in wine aroma. Arch. Biochem. Biophys. 2009, 483 (2), 236–245.

[6] Hernandez-Orte, P.; Cersosimo, M.; Loscos, N.; Cacho, J.; Garcia-Moruno, E.; Ferreira, V. Aroma development from non-floral grape precursors by wine lactic acid bacteria. Food Res. Int. 2009, 42 (7), 773–781.